STOP DIGGING’S SCREWS REPLACE CONCRETE FOUNDATIONS –

WHAT IS A GROUND SCREW FOR?

Ground screws are durable steel screws installed in the ground to provide a strong foundation for structures like buildings, decks, and fences without needing concrete.

Are you trying to decide between using concrete blocks or ground screws? There’s no need to ask: There’s a ground screw for every project.

Beam screw, post screw, adapter screw and pipe screw – we have four basic models of screw with different brackets, lengths and measurements depending on what is to be anchored, what the load requirements are and the ground conditions where the screws are to be installed.

As well as all this, we have a number of attachments for special installations. Where you need a concrete supporting block, we can install a screw!

OUR SCREWS AND ATTACHMENTS

WE HAVE THE GROUND SCREWS FOR ALL YOUR NEEDS

SGC ADAPTER SCREWS

Our universal screw SGC has a round plate with several slots for attachments and the size of the plate allows a large adjustment space in two joints. The large dimensions of the screw in combination with an extra thick zinc coating make it strong and durable, and thus suitable for heavier work.

USES INCLUDE:

Prefabricated buildings

Solar panels

Fence panels and barriers

SGP ADAPTER SCREWS

Our SGP adapter screw has a central hole in the head along with strong threads, making it suitable for many different purposes. The design allows for precise adjustment, so it’s perfect for projects that need flexibility but have lower load requirements.

USES INCLUDE:

Prefabricated buildings

Solar panels

Fence panels and barriers

SGU BEAM SCREWS

Our beam screws are the right choice when you want to install a foundation of horizontal joists, such as a floor for a hut or the supporting beams for a wooden deck. The screws are available in five lengths, which makes it possible to accommodate differences in ground levels while maintaining stability, just by using the screws.

USES INCLUDE:

Wooden decks

Huts

SGN PIPE SCREWS

The pipe screw is exactly what it sounds like – a tube-shaped ground screw intended to hold an elongated or cylindrical object inside it. It’s available in several dimensions for different needs. When the pipe screw is mounted, you only need to lower what is to be anchored and fix it with four bolts. It’s quick and easy.

Uses include:

Signage

Parks

Barriers

SG EX ADAPTER SCREWS

SGC EX are comprised of three parts. A base screw, an extension section , and a top section with mounting plate. With these extendable ground screws you can continue to build until you have reached the depth, or capacity, you need.

Uses include:

Prefabricated buildings

Fence panels and barriers

SGS POST SCREWS

Now you can stop using concrete foundation blocks for good. Our ground screws get the job done more quickly and easily but are just as stable as traditional posts. The screws are available in two different standard widths to suit your project.

Uses include:

Carport

Fence

WE ARE WHERE YOU ARE. CONTACT US.

GROUND SCREWS

FROM STOP DIGGING

WIN EVERY MATCH

READ MORE ABOUT THE BENEFITS OF USING GROUND SCREWS

STOP DIGGING’S GROUND SCREWS ARE SPECIALLY DEVELOPED FOR THE NORTHERN CLIMATE AND MAINTAIN THE HIGHEST QUALITY IN ALL RESPECTS

All our screws come with a 25-year guarantee

Our screws are

CE-certified

The material

used in

the screws is steel,

ISO 630 Fe 360A

The outer part of the

screws is galvanised according

to DIN EN ISO 1461

The production process

is certified according to

ISO 9001

FAQ – COMMON QUESTIONS

Ground screws – how, where and when?

We have the answers.

Each construction project has unique conditions and requirements, but our ground screws are versatile and are able to provide substantial anchoring of your projects, large and small. If you don’t find the answer to your question here, don’t hesitate to contact us.

01 Why use ground screws?

Ground screws make construction projects easier. With no digging, pouring concrete, or waiting required, they save time, effort, and the environment. Ideal for a variety of soils and can be installed all year round. Ground screws allow immediate use of the foundation, making your construction projects faster and less intrusive.

StopDigging’s ground screws should not be confused with the type of ground screw or anchor screw sold at DIY stores. StopDigging’s innovative ground screws are always delivered with complete installation by our authorised installers.

02 Can you install ground screws yourself?

Some ground screws can be installed by hand. The ground screws we have designed are needed to be installed by one of our professionals using tools we have designed.

We carry out work for both private individuals and companies, and all our fitters are certified. We have, among other things, delivered foundations to NCC, Skanska, Peab, Riksbyggen and several municipalities around Sweden.

03 What do you use ground screws for?

Ground screws can be used as foundations in many construction projects. Ground screw foundations are suitable for patios, park benches, rubbish bins, signs, fences, noise barriers, carports, recycling storage sheds, bicycle storage, garden rooms, SIPS extensions and much more.

We have smart solutions and lots of ways to work with specific projects. If you have a project we have the ground screws for it!

04 How deep do ground screws go?

How deep the ground screws need to be anchored depends on the load and the prevailing ground conditions. Our screws come in lengths from 580mm to 2500mm, to be able to create stable foundations in most soil types and construction projects. We also have an extendable format for depths far exceeding these lengths. We help you choose the right screw for each project and location.

05 How long do the ground screws need to be?

The length of ground screw you need varies depending on the soil condition, load and of course what type of project it is. We have four different types of screw – adapter, pipe, pillar and beam screw. These come in various lengths and dimensions to be able to meet all your requirements. As well as this, our ground screws have a number of specially designed attachments for different types of specific installations, such as fencing and flagpoles. All our ground screws are made for our Nordic climate with dimensions adapted to Swedish construction standards.

06 Can you install ground screws on rocky ground?

We always pre-drill a test hole before installing the ground screws. Smaller rocks are pushed away by the pre-drilling, medium-sized rocks get broken down. We have different solutions depending on the situation that arises. Our authorised fitters receive thorough training and have vast experience of solving such problems.

If there are rocks where you are going to build, there is a good chance that our installers can drill holes in the rock and anchor with a steel stud or steel post bracket. If your building, for example a wooden deck, is partly over a rock, we investigate the solution on-site, and make decisions on a case by case basis. In newly excavated soil, we need to take extra account of any subsidence in order to be able to perform a good and stable installation of ground screws, by choosing a longer screw, for example.

Our ground screws even work on steep slopes where you might want to anchor, for example, a staircase, build a terrace or install play equipment. Stop Digging’s screws are available in different lengths and together with our attachments, including plates and L-support, we can install even in tricky areas.

07 Can you install ground screws during a frost?

We can install ground screws all year round. Our earth screws are specially developed to withstand harsh conditions and the Nordic climate. Do you want to find out more? We are happy to help you with more information and example reference projects.

08 How strong are ground screws?

Our ground screws are made of ISO 630 FE 360 steel and the screw thickness and surface coating are specially developed and adapted to the Nordic climate. All our earth screws are hot-dip galvanised according to ISO 1461. All products are CE certified and manufactured in accordance with EN 1090-1: 2009. Our production facilities are also ISO certified in accordance with ISA 9001. Our screws have an expected lifespan of at least 100 years*.

*Stop Digging stipulates an estimated minimum lifetime for its ground screws. The amount reflects the number of years an installed screw is expected to fulfill its technical purpose under normal conditions, and is based on many years of experience and research.

09 Does subsidence affect ground screws?

In the same way as concrete foundation posts, ground screws can also be affected by subsidence in the ground, but our steel ground screws are generally not affected by frost. In newly excavated soil, we need to pay special attention to this in order to be able to fit a good and stable installation of ground screws, for example, by choosing a longer screw.

10 How much weight can ground screws hold?

Our ground screws can withstand different loads, pressures and weights. Whatever your construction project, we will have a ground screw that will meet your needs. All our ground screws are thoroughly tested to meet load, pressure and tension-bearing requirements. Read more about our screws here. These values are the result of several tests in different soil types and can be affected by different soil conditions. To ensure local conditions, we can perform a tensile test.

11 What certification does your ground screws have?

Our steel earth screws are specially developed, and the thickness and surface coating has been adapted to the Nordic climate. All our earth screws are hot-dip galvanised according to ISO 1461. They are CE certified and our production facilities are ISO certified in accordance with ISO 9001.

12 How much do ground screws cost?

We offer a fixed price according to a quote. However, our prices vary depending on which ground screw you need to use and where in the country you are. All projects have unique requirements, and the price will reflect this. Contact Stop Digging for a free quote.

SPECIAL INSTALLATION

ATTACHMENTS

Our ground screws have a number of attachments for different types of special installation. With the help of our smart accessories, our screws can be used to anchor building fences, sheds, flagpoles, noise barriers and solar panels, among others.

We can also develop special attachments for your particular project that are perfectly suited to your needs. Contact us for more information.

CONSTRUCTION FENCE BRACKETS

These are best combined with a pipe screw with a diameter of 67mm. It’s quick and easy to install these screws exactly where they are needed. Combined with the special bracket adapted for standard construction fencing, the result is stable and secure anchoring.

FLAGPOLE BRACKETS

A special bracket that works in combination with one or three ground screws depending on the height of the flagpole.

NOISE BARRIER BRACKETS

These are examples of different mounts, but each project is unique and the attachments and mounts are ordered based on the project requirements.

ATTACHMENTS FOR MANY PURPOSES

SGF

SGE

SGL

SGC Plate

Plate 150x150

BARACK BRACKETS

single

BARACK BRACKETS

double

ADVANTAGES OF USING THE SCREWS

SPECIAL ATTACHMENTS

WITH GROUND SCREWS

For our ground screws, there are a number of attachments for different types of special installation, including beam brackets of 70mm, post brackets (70mm), plates (150×150mm) and L-supports – all of which also work with our adapter screw. With the help of our well thought-out accessories, our screws can be used to anchor flagpoles, noise barriers, solar panel systems and construction fences, among other projects.

As you can see, there are not many limitations to the uses of our ground screws. So don’t hesitate to contact us with any questions or a challenging assignment – we are ready to develop a solution, and the right anchoring for your project, quickly and cost-effectively!

INSTALLATION EVERYWHERE, ALL YEAR ROUND

GROUND SCREW INSTALLATION – HOW IT WORKS

Before installing the screws, all holes are pre-drilled to make the screws easier to attach. The pre-drilling also gives us an idea of the prevailing soil conditions so that we can choose the right length and location of each screw. Our technology can handle all types of soil – compact clay is not a problem, and smaller rocks can move or crack. If we encounter large stones or rocks, we can either adjust the location of the screw or put a stud in the stone. In porous soil or sand, we use our longest screw.

Installation is quick and easy, it only takes a few minutes per screw. The ground screws are installed with the help of our specially developed machine which has extremely high torque. It can even install screws when the ground is covered by frost. The machine does not damage grass or other surfaces. If you need a foundation built in an area covered by cobblestones, we just lift a stone and drill. Similarly, if there is asphalt we can easily make a nice tidy hole for the screw.

*Stop Digging stipulates an estimated minimum lifetime for its ground screws. The amount reflects the number of years an installed screw is expected to fulfill its technical purpose under normal conditions, and is based on many years of experience and research.

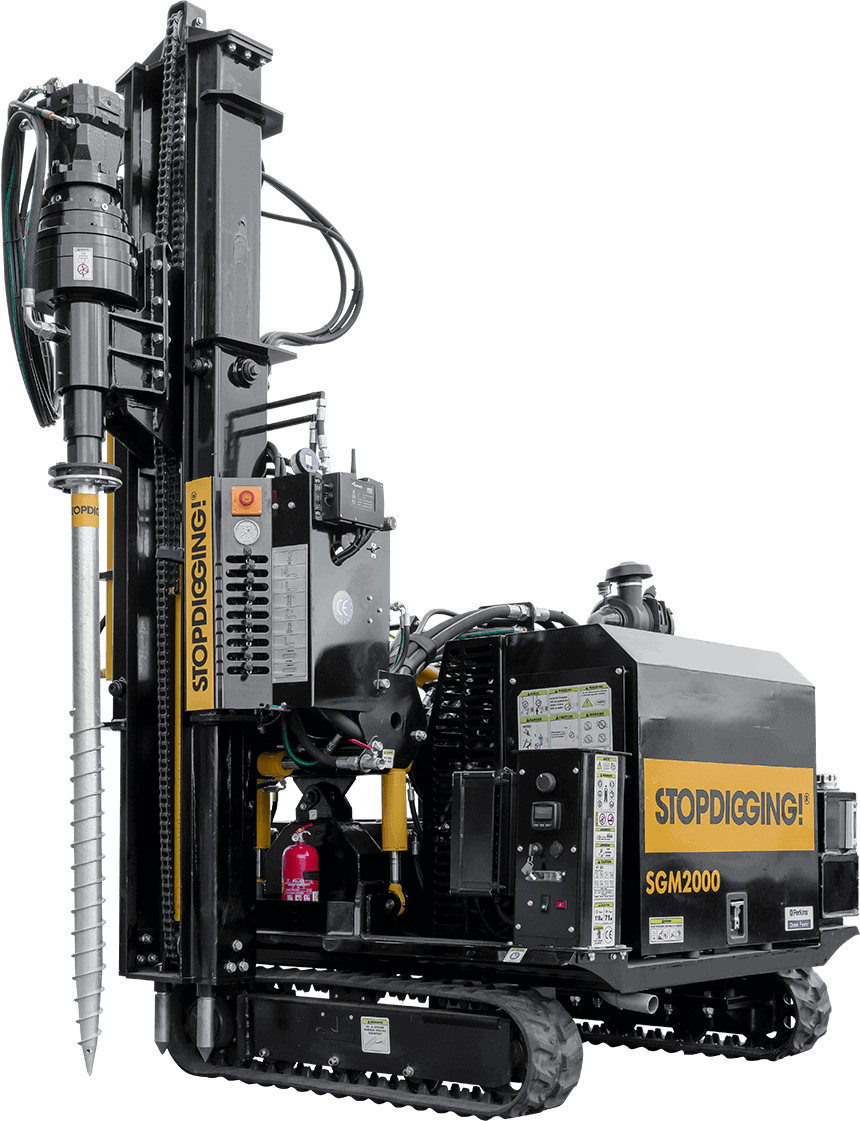

OUR MACHINE PARK

SPECIALLY DEVELOPED MACHINES

SGM06

SGM06 is made in Germany and has been specially adapted for Stop Digging. It comes with a sturdy, specially constructed bag to contain the machine and all its accessories. The machine is powered by a strong motor of 1700 Watts and produces approximately 4800Nm of torque. In other words, the SGM06 can install our largest ground screws in almost all ground conditions.

SGM07

The SGM07 is the latest addition to our handheld machine portfolio and the strongest machine yet. With a high-powered electric motor, the SGM07 produces 5300 Nm of torque and has an unloaded speed of 20 rpm in high gear mode. In other words, the SGM07 is capable of handling larger installations and in most conditions.

High volume machines

SGM2000

SGM2000 is our biggest and most advanced installation machine. With a hydraulically adjustable rig, large torque and a retractable system, the SGM2000 installs ground screws at very high speed and with great efficiency. The machine also has the option to be fitted with equipment for logging torque in real-time, full GPS positioning and a pneumatic DTH drill for very hard surfaces.

BEING CERTIFIED MEANS YOU GET HIGH QUALITY

CERTIFIED INSTALLERS

Stop Digging’s installers undergo rigorous training in using our specialised equipment. They have the right skills and understanding to offer our clients the best solutions for their needs.